I feel I need to write a history of my experience with Fort Howard Paper Company, but I find it hard to get started. After all, I spent 16 years with them, the longest tenure with anyone in my working career and I should have something to say about all that time. In truth, much of it is a blur and there is a lot I do not remember clearly, perhaps because there was so much going on in my personal life at that time. Additionally, I never felt in sync with the culture of the company and always looked at it as a job. Many others in the company were very invested in their career there, I never was.

So, here goes, this is what I remember and/or think is important and/or want to write about.

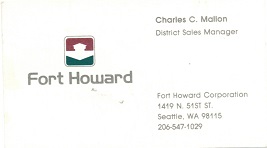

I was hired by Fort Howard Paper Company April 6, 1983 as the Los Angeles District Manager with a salary of $37,000/yr by Bill Yarnall. I knew Bill from my days at Scott Paper, where I had worked for ten years. For some reason that now escapes me, Bill had left Scott to go to work for Fort Howard about a year earlier as their West Coast Division Manager. He needed to replace the district manager in Southern California and, with my experience at Scott Paper, I was a good fit. I had just sold a Management Recruiting franchise in Seattle that I had started up 18 months earlier in partnership with another friend from Scott, Don Urie. I did not do well in the recruiting business for a variety of reasons and was happy to get away from it and have a job with a salary, car and benefits. So I moved from Seattle to Hermosa Beach, California with my girlfriend at the time, Constance Grecco.

I was hired by Fort Howard Paper Company April 6, 1983 as the Los Angeles District Manager with a salary of $37,000/yr by Bill Yarnall. I knew Bill from my days at Scott Paper, where I had worked for ten years. For some reason that now escapes me, Bill had left Scott to go to work for Fort Howard about a year earlier as their West Coast Division Manager. He needed to replace the district manager in Southern California and, with my experience at Scott Paper, I was a good fit. I had just sold a Management Recruiting franchise in Seattle that I had started up 18 months earlier in partnership with another friend from Scott, Don Urie. I did not do well in the recruiting business for a variety of reasons and was happy to get away from it and have a job with a salary, car and benefits. So I moved from Seattle to Hermosa Beach, California with my girlfriend at the time, Constance Grecco.

Fort Howard, headquartered in Green Bay, Wisconsin, was the major low cost sanitary paper (towels, tissue, napkins and wipers) manufacturer in the nation. They sold their products through a network of distributors to the away-from-home market (not grocery stores) and were market volume leaders in all parts of the country except for the west coast. All their products were made from relatively inexpensive recycled paper, something at that time our competitors, whose raw material was virgin wood pulp, used to sell against us. With the public’s growing concern for environmental issues, this weakness, over time, became a strength.

As the Los Angeles District Manager I had about 6-7 representatives assigned to me. With a few exceptions, I found them fairly average in talent, under trained and poorly motivated. The reason for this soon became apparent; Fort Howard’s salary schedule for that part of the country was not competitive. We could not hire good quality salespeople, unless it was their first job and they needed to get their foot on the first rung of a career ladder. If any of our people developed into good employees, we would soon lose them to another company willing to pay more, including our competitors. We thus continually lost our good people and remained stuck with the duds.

I did become good friends with one of the many hires we went through at this time. Dai Morgan had come over from Wales to play rugby at Long Beach State. He turned out to be an excellent salesman. I went with him back to the UK on several Rugby themed trips. He eventually met his wife at my wedding in Seattle. Over the years we have lost contact.

Despite alerting upper management to the problem with compensation and repeatedly requesting upgrades in our remuneration packages, it never changed. Due to this it continued to have a profound impact by limiting our ability to build good sales teams. It was also the major reason I could never fully commit to the company.

I believe the reasons for this deaf ear to the reality of the marketplace by company leaders was due to the headquarters being located in Green Bay, that the company was the industry’s low cost producer and that they were wholly manufacturing oriented.

Green Bay in 1983 was an old mid-west mill town with a world-class football team and a populations of about 100,000. For those who did not go to college, getting a job at the Fort Howard Mill (proudly non-union) meant that they were set for life. The company had started locally years ago and had prospered to become a major corporation by the 1970’s. Loyalty to the company was strong. But the company was small town-centric and many company-wide decisions were based upon local upper-state Wisconsin norms. A good salary in Green Bay was not a good wage in Los Angeles, nor in most of the rest of the country as well. Additionally, the hard working employees there often lacked awareness and worldliness. Suggestions for change, from salaries and products to marketing, were often met with some form of “why should we change, this is how we have always done things and look how successful we are?”

And, the famous sign reading “Tittle Town” at one entrance to the city, referring to the Green Bay Packers glory years, was rusted.

Please understand, these were fine people, it was just that I was from a different corporate environment and never felt, as I said earlier, in sync with the company ethos.

I believe much has changed there since the time I am writing about.

Low Cost producer: As mentioned above, Fort Howard made their paper products from relatively inexpensive recycled paper, as opposed to the more costly tree-sourced “virgin” pulp that our main competitors like Scott Paper and James River were using. Although many end users felt that our products were of lower quality than those of other manufacturers, the company always had the flexibility to find a pricing level that made the Fort Howard product the better value. So much of the time, especially before being made of recycled paper came into vogue, our products were sold on price. I always felt that our company viewed their national “sales force” , not as an entity to “sell” the product, the people in Green Bay who controlled the pricing would do that. I believe upper management looked at us as a necessary evil that was in place to maintain contact with distribution and end users as well as to send market (price) information back to the real decision makers at HQ. There was little emphasis on feature and benefit selling.

Wholly manufacturing oriented: During an earlier time when I was with Scott Paper, there were often paper shortages during which manufactures could not keep up with the demands of the marketplace for disposable towels, tissues and napkins. For this reason a good relationship with a reliable manufacturer of these items was of primary importance to the distribution community. Because of this we were able to retain good profit margins and raise prices regularly. We were also able to be selective in the distributors we sold to. They were motivated to meet our mutual sales goals so that we would not be “forced” to expand our franchise in their market to their competitors. But with the high profits available in our industry, conditions began to change. As I left Scott, we and our competitors started a paper-machine-building war to take advantage of this money making opportunity. And, no one more so than Fort Howard, who eventually expanded from their one mill in Green Bay to additional facilities in Muskogee, Oklahoma and Rincon, Georgia. Each mill contained multiple paper making machines at a price of approximately $250,000,000 each to build in 1980’s dollars. Suddenly there was an oversupply of sanitary paper products and a lot of pressure on the sales force to move it. Prices were cut and elaborate rebate programs were set up for distribution. Within a few years the leverage in negotiations changed from manufactures who controlled the product to distributors who controlled the market (the end users to whom they sold).

There was something else at Fort Howard that was new to me. With their extensive line of paper napkins, they were in a strong position with food service distributors and it represented a significant portion of their business. As I was leaving Scott, they were just getting into food service items, but Fort Howard really dominated the market. This of course meant I was dealing with these food service distributors a good deal of my time. They were different from the paper and janitorial distributors I was accustomed to working with. These traditional types of distributors were not only looking for a good price, but also a partnership that provided them with innovative products, training for their sales representatives and help selling to the end user. While food service distribution was also looking for these things, they were much more centered on “what is your price today and what type of rebate programs can you set me up on”. I believe this was mostly a reflection of the type of end users they called on. Restaurants wanted the best price and could not care less about other concepts. It wasn’t much fun to be so often in an environment where your future depended upon your next deal.

Another change that was occurring in the sanitary paper industry was the consolidation of distributors as the big fish bought up their smaller competitors. This meant that we had fewer clients upon which to call and that each one of these was important to our annual volume goals. Lose one of these accounts, or just get de-emphasized with them, and the whole year could be ruined.

Just at the time I joined Fort Howard in 1983 they purchased Sweetheart Cup. Sweetheart was a Baltimore based company that was started years ago by immigrant brothers from Russia. They originally made ice cream cones and, over time, expanded into disposable cups, containers, utensils, etc. for the take-away food industry. Fort Howard looked at it as a natural extension to their food service line. They were especially interested in a new thin foam-like hot cup technology that Sweetheart had developed and called “Trophy Cup. This merger did not go well for a number of reasons. My impression was that the Sweetheart systems and facilities were tired and outdated. In 1985 We attempted to integrate their sales force and supply chain into ours and it was a disaster. My sense was that many on the Sweetheart side did not want this to happen and put little effort into the process. Lost and delayed orders, lids and cups that did not fit, billing issues, deductions from bills by distributors, etc. made this marriage a nightmare.

started years ago by immigrant brothers from Russia. They originally made ice cream cones and, over time, expanded into disposable cups, containers, utensils, etc. for the take-away food industry. Fort Howard looked at it as a natural extension to their food service line. They were especially interested in a new thin foam-like hot cup technology that Sweetheart had developed and called “Trophy Cup. This merger did not go well for a number of reasons. My impression was that the Sweetheart systems and facilities were tired and outdated. In 1985 We attempted to integrate their sales force and supply chain into ours and it was a disaster. My sense was that many on the Sweetheart side did not want this to happen and put little effort into the process. Lost and delayed orders, lids and cups that did not fit, billing issues, deductions from bills by distributors, etc. made this marriage a nightmare.

started years ago by immigrant brothers from Russia. They originally made ice cream cones and, over time, expanded into disposable cups, containers, utensils, etc. for the take-away food industry. Fort Howard looked at it as a natural extension to their food service line. They were especially interested in a new thin foam-like hot cup technology that Sweetheart had developed and called “Trophy Cup. This merger did not go well for a number of reasons. My impression was that the Sweetheart systems and facilities were tired and outdated. In 1985 We attempted to integrate their sales force and supply chain into ours and it was a disaster. My sense was that many on the Sweetheart side did not want this to happen and put little effort into the process. Lost and delayed orders, lids and cups that did not fit, billing issues, deductions from bills by distributors, etc. made this marriage a nightmare.

started years ago by immigrant brothers from Russia. They originally made ice cream cones and, over time, expanded into disposable cups, containers, utensils, etc. for the take-away food industry. Fort Howard looked at it as a natural extension to their food service line. They were especially interested in a new thin foam-like hot cup technology that Sweetheart had developed and called “Trophy Cup. This merger did not go well for a number of reasons. My impression was that the Sweetheart systems and facilities were tired and outdated. In 1985 We attempted to integrate their sales force and supply chain into ours and it was a disaster. My sense was that many on the Sweetheart side did not want this to happen and put little effort into the process. Lost and delayed orders, lids and cups that did not fit, billing issues, deductions from bills by distributors, etc. made this marriage a nightmare.

In other words Fort Howard had their issues like any other company of their size and I felt fortunate at that time to be hired to help them work through some of them.

Los Angeles District Manager April 1983 to April 1985

I threw myself into the job. First I spent time getting to know the distributors and doing a lot of training and “ride-withs” with the

sales force. We had some significant turn over of personnel, some because they didn’t like the changes we initiated. But we got good results and we were awarded District of the Year one or two times. As the past record in LA was so poor, winning these was not that hard and meant little to me.

I lived a block from the beach and enjoyed going home each evening from the heat and smog of the LA basin to the laid-back coastal atmosphere. I often ran on the beach , followed by a few minutes of body surfing. Of course it cost more to live there but I felt it was worth it. Writing this I can still smell the ocean and feel the breeze.

After two years there was an opening back in Seattle for the same level job of District Manager that I had in LA. My friend and boss, Bill Yarnall, to my every lasting appreciation, transferred me back up there. He got flak from Green Bay over this, as Los Angeles was a much bigger market, but countered truthfully that if Fort Howard did move me back, I would probably do it myself with a different employer when the first opportunity came along.

Seattle District Manager April 1985 to April 1991

I was happy to be back in the Northwest, I never planned to leave. The market environment and the condition of the sales force were much the same as I had found in Los Angeles. But we started to turn things around and would win a number of District of the Year awards.

The big challenge for me, as well as everyone else in the company, is that we attempted to integrate Sweetheart into our sales force at this time. There were so many screw ups (some perhaps intentional) and I knew so little about that product line, that every day was difficult. I can remember a number of times, as early as 10:00 a.m., laying on my back on the floor in my home office, trying to let the tension flow out of me.

In 1991 I was invited to interview for the Western Division Managers position, then located in Dallas. This was not something I wanted to do, but ended up being offered and accepting the new opportunity. See the details here.

Western Division Manager Boulder, Colorado April 1991 to August 1999

I spent the first six months working out of the old Division office in Dallas before we could get things moved to Boulder. As there were many re-organizations of territories over the years that I was a Division Manager, at one time or another I was responsible for most of the geography west of Missouri River. I usually had 4 or 5 district managers reporting to me and they in turn had 5 to 7 sales reps each. Our Division office was in downtown Boulder and we had an office manager there.

I have often described this position as flying out on Monday morning to go to places I did not want to go to, to see people who did not want to see me and return on Friday to a weekend of paperwork, only to be repeated the following week. While this is of course an exaggeration, it does express some of my feelings for the job. Additionally, true to Fort Howard’s philosophy, I was significantly underpaid for this level of responsibility.

One good thing that did happen over this time was that the concept of “recycled” became much more desirable, which cast those representing Fort Howard into a more positive competitive position.

In 1997 Fort Howard and James River merged and became James River. It is apparent now in retrospect that the goal of this new entity was to drive up profits, by any short term means possible, to put the company into a good position to be sold.

In 1997 Fort Howard and James River merged and became James River. It is apparent now in retrospect that the goal of this new entity was to drive up profits, by any short term means possible, to put the company into a good position to be sold.

Truthfully, for the last few years I had been just going through the motions necessary to keep my position going. With the new Fort James philosophy in place of reporting in each week with the new deals we had been able to cut with distribution to drive in yet more volume, I reached a point where I no longer cared and of course this became evident to my management. Based upon my longtime service with the company, I was offered a demotion, at no loss in salary, to the Denver District Managers position. I turned this down, as I was completely burned out on anything to do with the organization, and accepted a termination package. So my career with Fort Howard/Fort James died a quiet death.

So, if I was so uncommitted to this employer, why did I not leave them much sooner? Well, I have no good answer for that other than that no one else offered me a position that I was interested in and my poor experience with going out on my own with Management Recruiters was such a failure, I was hesitant to try something like that again. Additionally, all my significant business experience had been in the away-from-home sanitary paper business and I did not feel I could duplicate my salary outside that industry.

Wow, what an amazing, honest, grounded, intelligent article. I was with Ft. Howard Paper Company in 1983 training in Big Bear, California. I remember some of the guys in the Photo above.I came from John Deere Corp., Italy and had been a marketing manager, trainer, and Founder of a company in Italy (Fiorentini S.P.A. Industrial cleaning equip. worldwide) and due to my efforts today it is worth billions of dollars in 113 countries. Alessandro Fiorentini still today thanks me for what I did with his father in 1981. Ft Howard did not see much WORTH IN ME. They treated me like I was just another number and warm body to throw into the field. I left Ft Howard for Statewide Foodservice as Vice president and built a salesforce from scratch. Doing so well Best Foods/CPC Intern'l hired me at much higher salary and benefits, car, bonus and more as Regional Mgr. 9 Western States. I stayed with them 10 years and was very successful. If not for Cancer and spinal injury caused by BF in a warehouse I would have become president of BF or Knorr Swiss, Switzerland my ultimate goal as I own a home in Italy with my Italian wife. Thank you for amazing article. I often wondered over the years if I made the right decision leaving Ft Howard 'during training'. I purposely failed the first test to leave but, not in the smartest manner. lol I just wanted out. They truly made us feel worthless. Thank you sir and I am sorry about the career. The moves you were forced to make. We must live for today and keep moving forward. Hell with yesterday! Cancer showed me this. Bless you. James H Hall, 1983 Ft Howard

ReplyDelete